Smoke and carbon monoxide detectors are unsung heroes of home safety, silently guarding against invisible threats. These life-saving devices offer crucial protection from the dangers of smoke inhalation and carbon monoxide poisoning, two silent killers that can strike without warning. Understanding the different types of detectors, their proper placement, and regular maintenance is essential for ensuring your family’s well-being.

This guide delves into the science behind these devices, offering practical advice for maximizing their effectiveness and keeping your home safe.

From choosing between ionization and photoelectric smoke detectors to understanding the chemical reactions within carbon monoxide detectors, we’ll explore the intricacies of these vital safety systems. We’ll also cover best practices for installation, testing, and maintenance, equipping you with the knowledge to confidently protect your loved ones.

Types of Smoke Detectors: Smoke And Carbon Monoxide Detectors

Source: preparednessadvice.com

Smoke detectors are crucial for home safety, providing early warnings of potentially life-threatening fires. Understanding the different types available helps you choose the best protection for your specific needs. Two main types dominate the market: ionization and photoelectric detectors. Each operates on a different principle, leading to varying strengths and weaknesses.

Ionization Smoke Detector Operation

Ionization smoke detectors use a small amount of radioactive material (americium-241) to ionize the air between two electrodes. A small electrical current flows between these electrodes. When smoke particles enter the chamber, they disrupt this current, triggering the alarm. This type is generally more responsive to fast-flaming fires, which produce smaller, more rapidly moving particles.

Photoelectric Smoke Detector Operation

Photoelectric smoke detectors employ a light source (usually an LED) and a photoelectric sensor. Smoke entering the chamber scatters the light emitted by the LED, and this scattered light is detected by the sensor, triggering the alarm. This type is typically more sensitive to smoldering fires, which produce larger, slower-moving smoke particles.

Advantages and Disadvantages of Ionization Smoke Detectors

Ionization detectors are generally less expensive and have a faster response time to fast-flaming fires. However, they are less sensitive to smoldering fires, which can be more dangerous as they often develop slowly and produce less visible smoke. The presence of the radioactive material, while in tiny amounts and considered safe by regulatory bodies, can be a concern for some people.

Advantages and Disadvantages of Photoelectric Smoke Detectors

Photoelectric detectors are more sensitive to smoldering fires, offering earlier warnings for these slower-burning, more insidious types of fires. They are generally considered more reliable for detecting fires that start slowly and produce larger smoke particles. However, they may have a slightly slower response time to fast-flaming fires compared to ionization detectors and are typically more expensive.

Smoke and carbon monoxide detectors are vital for home safety, providing early warnings of potential dangers. But for a complete home security system, consider adding another layer of protection with Home surveillance cameras , which can alert you to issues even when you’re away. This combined approach ensures you’re prepared for a wide range of emergencies, from fires to break-ins, giving you peace of mind knowing your home is protected.

Situations Favoring Specific Detector Types

A fast-flaming fire, such as one caused by a grease fire in the kitchen, might be detected more quickly by an ionization detector. Conversely, a smoldering fire in a basement, potentially caused by faulty wiring, is more likely to be detected sooner by a photoelectric detector. The presence of pets, which can sometimes trigger false alarms in ionization detectors due to dust or hair particles, might make a photoelectric detector a more suitable choice.

Comparison Table, Smoke and carbon monoxide detectors

| Detection Type | Response Time | Cost | Maintenance |

|---|---|---|---|

| Ionization | Faster to flaming fires | Lower | Regular cleaning; replace every 10 years |

| Photoelectric | Faster to smoldering fires | Higher | Regular cleaning; replace every 10 years |

Carbon Monoxide Detector Functionality

Carbon monoxide (CO) detectors are crucial for home safety, silently protecting occupants from the invisible and odorless threat of this poisonous gas. Understanding how these devices work is key to appreciating their life-saving potential. They function by detecting the presence of CO in the air and triggering an alarm to warn residents.CO detectors primarily rely on electrochemical sensors to detect the presence of carbon monoxide.

These sensors utilize a chemical reaction to measure the concentration of CO in the surrounding air. The reaction involves the oxidation of carbon monoxide at an electrode, generating an electrical current proportional to the CO concentration. The higher the CO level, the stronger the current, and the faster the alarm will sound.

Electrochemical Sensors in Carbon Monoxide Detectors

Electrochemical sensors are the most common type used in CO detectors. They typically consist of two electrodes (an anode and a cathode) separated by an electrolyte. When CO enters the sensor, it reacts with oxygen at the anode, releasing electrons. These electrons flow through the external circuit to the cathode, creating a measurable electrical current. The magnitude of this current is directly related to the concentration of CO.

The specific chemical reaction is complex, involving several intermediate steps, but the overall process can be simplified as: 2CO + O₂ → 2CO₂ + 4e⁻. The electrons released in this oxidation process are what generate the electrical signal.

Other Types of Carbon Monoxide Sensors

While electrochemical sensors dominate the market, other sensor technologies exist, although they are less prevalent in consumer-grade CO detectors. These include semiconductor sensors, which utilize changes in electrical conductivity to detect CO, and infrared sensors, which detect the specific infrared absorption wavelengths of CO molecules. However, electrochemical sensors offer a good balance of sensitivity, cost-effectiveness, and long-term stability, making them the preferred choice for most applications.

Diagram of a Carbon Monoxide Detector’s Internal Components and Operation

Imagine a cross-sectional diagram of a typical CO detector. The outer casing protects the internal components. Inside, there’s a small electrochemical sensor, often a miniature fuel cell-like structure. This sensor sits within a chamber with small air intake holes, allowing ambient air to flow into contact with the sensor. The sensor itself consists of a porous material containing the anode and cathode, separated by an electrolyte.

Electrical wiring connects the sensor to a micro-controller which processes the signal from the sensor. If the CO concentration exceeds a pre-set threshold, the microcontroller activates the alarm, typically a loud buzzer or siren. A small battery powers the entire system. A LED indicator might also be present to display the detector’s status and any errors. The air flows through the intake holes, over the sensor, and out through vents.

The entire system is designed to be compact and easily mounted on a wall. The sensor’s reaction to CO produces a measurable electrical signal, which is amplified and processed by the microcontroller to trigger the alarm when the CO concentration reaches a dangerous level.

Placement and Installation

Source: homedepot-static.com

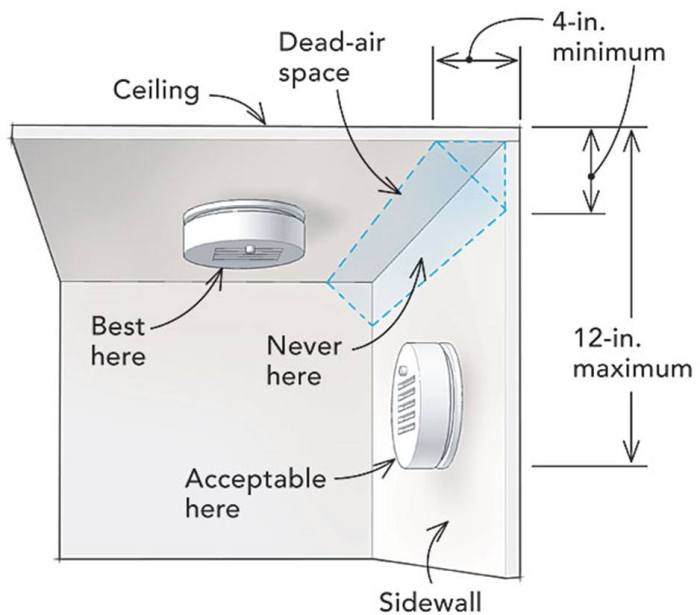

Proper placement and installation of smoke and carbon monoxide detectors are crucial for ensuring their effectiveness in protecting your home and family. Incorrect placement can significantly reduce their ability to detect dangerous levels of smoke or carbon monoxide, leading to potentially life-threatening situations. Understanding the best practices for installation is vital for maximizing the safety benefits these detectors provide.

Optimal placement maximizes the detector’s range and ensures that it can detect threats quickly. This involves considering factors such as air circulation patterns within the home, the proximity to potential sources of smoke or carbon monoxide, and the overall layout of the dwelling. Proper installation also includes following the manufacturer’s instructions carefully, ensuring the detector is securely mounted and properly connected to the power supply (if applicable).

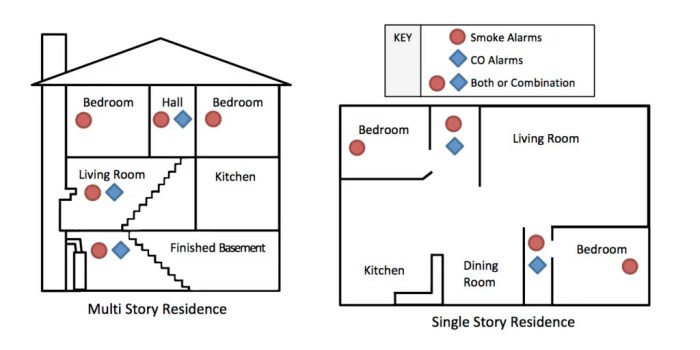

Optimal Detector Placement

Strategic placement is paramount for effective early warning. Detectors should be placed on every level of the home, including the basement and attic, as well as inside and outside sleeping areas. Consider the typical flow of smoke and carbon monoxide to determine ideal locations. Smoke tends to rise, so ceiling placement is often preferred, but wall mounting is acceptable, usually between 4 and 12 inches below the ceiling.

Importance of Proper Installation and Testing

Incorrect installation can render even the most advanced detectors useless. Common mistakes include mounting detectors too close to walls or corners, where airflow might be restricted, leading to delayed detection. Improper wiring or battery installation can also cause malfunctions. Regular testing, at least once a month, is essential to ensure that the detectors are functioning correctly and the batteries are working.

This involves pressing the test button on each detector to confirm that the alarm sounds.

Common Installation Mistakes

Several common errors compromise the effectiveness of smoke and carbon monoxide detectors. These include neglecting to install detectors on every level of the home, placing them too close to sources of heat or humidity (such as kitchens or bathrooms), failing to regularly test the devices, and ignoring low-battery warnings. Another significant mistake is improper wiring, particularly for hardwired detectors, leading to unreliable operation.

Smoke and carbon monoxide detectors are crucial for home safety, ensuring early warnings of potentially deadly hazards. You might even find some stylish, older detectors complementing the aesthetic of your home, perhaps tucked away near some beautiful Vintage cabinets. However, remember that detector placement is more important than aesthetics; ensure they’re strategically located for optimal protection.

Best Practices for Installing Detectors in Various Areas

Following best practices for specific areas ensures comprehensive protection. Different areas present unique challenges requiring tailored approaches for optimal placement and installation.

- Bedrooms: Install a smoke detector inside each bedroom, ideally on the ceiling or high on the wall. Carbon monoxide detectors are also recommended in bedrooms due to the risk of exposure during sleep.

- Kitchens: Smoke detectors in kitchens should be placed away from cooking appliances, ideally on the ceiling but at least 10 feet away from stoves and ovens. Consider the air circulation patterns to avoid false alarms.

- Living Areas: Install smoke detectors in living areas, hallways, and other common spaces, ideally on the ceiling. Placement should be central to provide maximum coverage.

- Garages: Carbon monoxide detectors are essential in attached garages, as exhaust fumes can easily seep into the house. Install the detector near the entrance to the living area.

- Basements: Install smoke and carbon monoxide detectors in basements, as these areas are often prone to accumulating smoke and carbon monoxide. Place them on the ceiling or high on the wall, away from potential sources of moisture.

Maintenance and Testing

Regular maintenance of your smoke and carbon monoxide detectors is crucial for ensuring your family’s safety. Neglecting this can lead to a false sense of security, potentially resulting in tragic consequences. A simple maintenance schedule and regular testing can significantly reduce the risk of a detector failure when you need it most.

Regular Maintenance Schedule

A proactive approach to detector maintenance involves more than just occasional testing. Aim for a comprehensive check at least twice a year, ideally in spring and fall, coinciding with seasonal changes and the start/end of heating season. This schedule allows you to check for dust buildup, which can impair sensor function, and verify the battery’s condition, ensuring optimal performance.

Additionally, inspect the detectors for any physical damage, such as cracks or loose components. This consistent monitoring helps to identify and address potential issues before they become serious problems.

Testing Detectors Using the Test Button

Most smoke and carbon monoxide detectors have a built-in test button. Pressing this button simulates an alarm condition, allowing you to verify that the device is functioning correctly. This simple test should be performed monthly. A properly functioning detector will emit a loud alarm sound, indicating that the internal components are working as intended. If the alarm does not sound, it’s a clear sign that the detector needs attention, possibly requiring a battery change or more extensive troubleshooting.

Troubleshooting Common Problems

A malfunctioning detector can stem from various issues. A common problem is a dead or low battery, easily remedied with a replacement. However, if the detector continues to malfunction after replacing the battery, it might indicate a problem with the sensor itself. In this case, consider replacing the entire unit. If the alarm is constantly sounding, despite no actual fire or carbon monoxide presence, check for dust accumulation near the sensors.

Smoke and carbon monoxide detectors are crucial for home safety, ensuring early warnings of potential dangers. For extra security, consider where you place them; you might even want to install them near less-obvious areas like inside hidden storage cabinets , depending on the cabinet’s design and ventilation. Proper placement of these detectors maximizes their effectiveness in protecting your home.

Thoroughly clean the detector according to the manufacturer’s instructions. Persistent problems after these steps necessitate contacting a qualified technician or replacing the detector.

Replacing Batteries in Smoke and Carbon Monoxide Detectors

Regular battery replacement is essential for maintaining the functionality of your detectors. Here’s a step-by-step guide:

- Locate the battery compartment. This is usually on the back or side of the detector. It may require a small screwdriver to open.

- Carefully remove the old batteries. Note the polarity (+ and -) to ensure correct installation of the new batteries.

- Insert the new batteries, matching the polarity markings.

- Close the battery compartment securely.

- Test the detector using the test button to verify proper functionality.

Interconnected Systems

Upgrading your home safety with interconnected smoke and carbon monoxide detectors offers significant advantages over individual units. A network of detectors provides enhanced protection and faster response times in emergency situations, improving overall home safety. This interconnectedness allows for a coordinated alarm response, alerting you to danger regardless of the location of the threat within your home.Interconnected systems work by allowing detectors to communicate with each other wirelessly or through hardwiring.

When one detector senses smoke or carbon monoxide, it triggers an alarm, and this signal is then relayed to all other interconnected detectors in the system. This ensures that everyone in the house is alerted simultaneously, even if they are sleeping or in a different part of the house. The communication method (wireless or wired) dictates the specific communication protocol used.

Wired Interconnected Systems

Wired systems offer a reliable and consistent connection between detectors. They are generally more expensive to install initially due to the requirement of running wires between each detector and a central control panel or power source. However, they are less susceptible to interference and offer a more robust and stable connection than wireless systems. The wiring usually involves low-voltage cabling and is often installed during new construction or major renovations.

A wired system generally involves a central control panel which manages the communication and alarm signals.

Wireless Interconnected Systems

Wireless interconnected systems use radio frequency (RF) signals to communicate between detectors. These systems are generally easier and less expensive to install as they don’t require any wiring between the detectors. They are highly flexible and can be easily expanded or relocated as needed. However, wireless systems are more susceptible to interference from other electronic devices or physical obstructions, potentially impacting the reliability of the signal transmission.

Battery life is a factor to consider, as regular battery replacements are necessary. Wireless systems typically use mesh networking, where each detector can relay signals to others, increasing overall network robustness.

Installing and Configuring a Simple Interconnected System (Wireless Example)

This example focuses on a wireless interconnected system. Always consult the manufacturer’s instructions for your specific model.First, select the desired number of detectors based on the size and layout of your home. Most manufacturers offer kits with multiple detectors, making setup easier. Install the detectors according to the manufacturer’s instructions, ensuring they are placed in optimal locations (typically on ceilings or high walls).

Next, power on the detectors (using batteries or a power adapter if applicable). The detectors will typically enter a pairing or learning mode automatically. Follow the instructions provided to link the detectors together. This often involves pressing a test or pairing button on each detector within a short time frame. Once the detectors are successfully paired, they will communicate with each other.

Test the system by activating the alarm on one detector. All connected detectors should sound simultaneously. Regular testing (at least monthly) is crucial to ensure the system functions correctly. Replacing batteries in accordance with manufacturer recommendations maintains reliable performance.

Safety Regulations and Standards

Ensuring the safety of homes and workplaces from the dangers of smoke and carbon monoxide requires adherence to specific safety regulations and standards. These regulations are crucial for protecting lives and property, and their enforcement is vital for public safety. Failure to comply can lead to severe consequences, highlighting the importance of understanding and following these guidelines.

Importance of Adhering to Safety Standards

Compliance with safety regulations for smoke and carbon monoxide detectors is paramount. These standards are based on extensive research and testing, designed to minimize risks and ensure the effectiveness of these life-saving devices. Following these regulations directly translates to a significantly reduced risk of fire-related deaths and injuries, as well as carbon monoxide poisoning. Proper installation, maintenance, and testing, as dictated by these standards, are not mere suggestions but essential steps for ensuring the detectors operate as intended and provide the necessary protection.

The economic consequences of non-compliance, such as property damage and legal liabilities, further underscore the importance of adherence.

Examples of Consequences of Non-Compliance

Ignoring safety regulations regarding smoke and carbon monoxide detectors can have devastating consequences. For example, a malfunctioning smoke detector due to improper installation or lack of maintenance could fail to alert occupants during a fire, leading to serious injury or even death. Similarly, a faulty carbon monoxide detector, or one placed incorrectly, could fail to warn of dangerous levels of this invisible, odorless gas, resulting in potentially fatal carbon monoxide poisoning.

In legal terms, non-compliance could expose homeowners or businesses to significant liabilities in the event of an incident. Insurance companies may also refuse to cover damages resulting from a failure to meet safety standards.

Key Safety Regulations and Standards

Several organizations establish safety regulations and standards for smoke and carbon monoxide detectors. These standards vary slightly by region but share common goals of ensuring the effectiveness and safety of these devices. Below are examples of key standards, though specific regulations may vary based on location and building codes. It’s crucial to consult local authorities and building codes for precise requirements.

The International Code Council (ICC) publishes building codes that often include requirements for smoke and carbon monoxide detectors.

UL (Underwriters Laboratories) provides safety standards for testing and certifying smoke and carbon monoxide detectors. UL certification indicates that a product has met specific safety requirements.

Remember to check your smoke and carbon monoxide detectors regularly – it’s a crucial safety measure for your home. While you’re focusing on home safety, sprucing up your kitchen can also improve your mood; perhaps check out some helpful resources like these Cabinet painting tips for a fresh look. After all, a safe and pleasant home environment is a priority, so don’t forget those detectors!

OSHA (Occupational Safety and Health Administration) sets standards for workplace safety, which often include requirements for smoke and carbon monoxide detectors in commercial and industrial settings.

NFPA (National Fire Protection Association) publishes standards related to fire safety, including the installation and maintenance of smoke alarms.

Local building codes often incorporate and supplement national standards, specifying requirements based on regional factors. Always check your local building codes for specific regulations.

False Alarms

False alarms from smoke and carbon monoxide detectors, while annoying, are a common occurrence. Understanding their causes and how to mitigate them is crucial for maintaining a safe and stress-free home environment. Frequent false alarms can lead to detector neglect, ultimately diminishing their life-saving potential.False alarms in smoke detectors often stem from everyday activities that create smoke or particulate matter, while carbon monoxide detector false alarms are less frequent but can still occur due to certain environmental factors.

Addressing these issues proactively minimizes disruption and ensures the detectors remain reliable when truly needed.

Common Causes of False Alarms

Several factors contribute to the triggering of false alarms. These range from simple cooking mishaps to more persistent issues like dust accumulation. Identifying the source is the first step towards preventing future occurrences.

Smoke and carbon monoxide detectors are crucial for home safety, ensuring early warnings of potential hazards. When renovating your kitchen, remember that safety extends to aesthetics too; consider stylish options like those shown in the amazing range of Cabinet door designs available online. Ultimately, though, the priority remains having functioning smoke and carbon monoxide detectors properly installed and regularly tested.

Reducing the Occurrence of False Alarms

Implementing preventative measures significantly reduces the likelihood of false alarms. Regular maintenance, proper placement, and addressing potential sources of interference are key strategies.

Responding to a False Alarm

Knowing how to handle a false alarm effectively is important. A calm and systematic approach ensures the situation is resolved safely and efficiently. Avoid dismissing the alarm immediately; investigate the cause first.

| Cause of False Alarm | Solution | Preventative Measures |

|---|---|---|

| Cooking (smoke, steam) | Ensure adequate ventilation while cooking; use exhaust fans. | Keep detectors away from cooking areas, if possible. Use a range hood. |

| Dust and debris accumulation | Vacuum or gently brush the detector’s sensors regularly. | Regular cleaning of the detector (as per manufacturer instructions). |

| Burning toast or other small fires | Quickly extinguish the source of smoke. | Supervise cooking, especially when using toasters or ovens. |

| Shower steam (in bathrooms) | Ensure adequate bathroom ventilation. | Avoid placing detectors in areas with high humidity. Consider a heat-resistant detector for bathrooms. |

| Insects or pests | Check for and remove insects or pests from the detector. | Regularly inspect the detector for signs of infestation. |

| Faulty detector (CO detectors) | Replace the detector. | Regular testing and replacement according to manufacturer’s recommendations. |

| High levels of humidity (CO detectors) | Ensure proper ventilation and lower humidity levels. | Avoid placing the detector in damp areas. |

| Other household chemicals (CO detectors) | Identify and remove the source of the chemical fumes. | Proper ventilation and storage of chemicals. |

Final Thoughts

Source: hermonmaine.gov

Protecting your home and family from the silent dangers of fire and carbon monoxide poisoning requires vigilance and proactive safety measures. By understanding the functionality, proper installation, and regular maintenance of smoke and carbon monoxide detectors, you can significantly reduce the risk of these devastating events. Remember, a functioning detector is your first line of defense – providing precious time to escape in the event of an emergency.

Prioritize regular testing and prompt replacement when necessary; it’s a small step that could save lives.

FAQ Explained

How often should I replace my smoke detector batteries?

Ideally, replace batteries once a year, or when the low-battery alarm sounds. Many newer detectors have longer-lasting lithium batteries.

What should I do if my smoke detector keeps going off for no reason?

Check for dust, insects, or cooking fumes near the detector. If the problem persists, it might need cleaning or replacing.

Can I use a smoke detector in my garage?

While possible, it’s generally recommended to use a carbon monoxide detector in the garage due to the risk of carbon monoxide buildup from vehicles and other equipment.

How long do smoke and carbon monoxide detectors last?

Most smoke detectors have a lifespan of about 10 years. Carbon monoxide detectors generally last around 5-7 years. Check the manufacturer’s recommendations.

What’s the difference between a hardwired and battery-powered detector?

Hardwired detectors are connected to your home’s electrical system, providing a continuous power source. Battery-powered detectors rely on replaceable batteries.